2021-2022 APOP Team

OSU and the Air Force: Partnering in new developments.

We are OSU's Aerospace Propulsion Outreach Program team, a collaboration between our university and the United States Air Force Research Laboratory.

Innovative Challenges

With OSU first participating in 2014, the Air Force-sponsored APOP competition is targeted at undergraduate students participating in capstone projects and motivated by the Air Force Research Laboratory’s Educational Partnership Agreements program. APOP is dedicated to aeronautical engineering endeavors specifically involving gas-turbine engine technology.

2021-22 Project

Primary Goals:

- Increase thrust-to-weight ratio by 60%

- Minimize thrust-specific fuel consumption decrement by 20%

- Produce cycle analysis model within 20% of actual performance values

Secondary Goals:

- Minimize propulsive and thermal efficiency detriment

- Decrease fuel flow rate

Subteams:

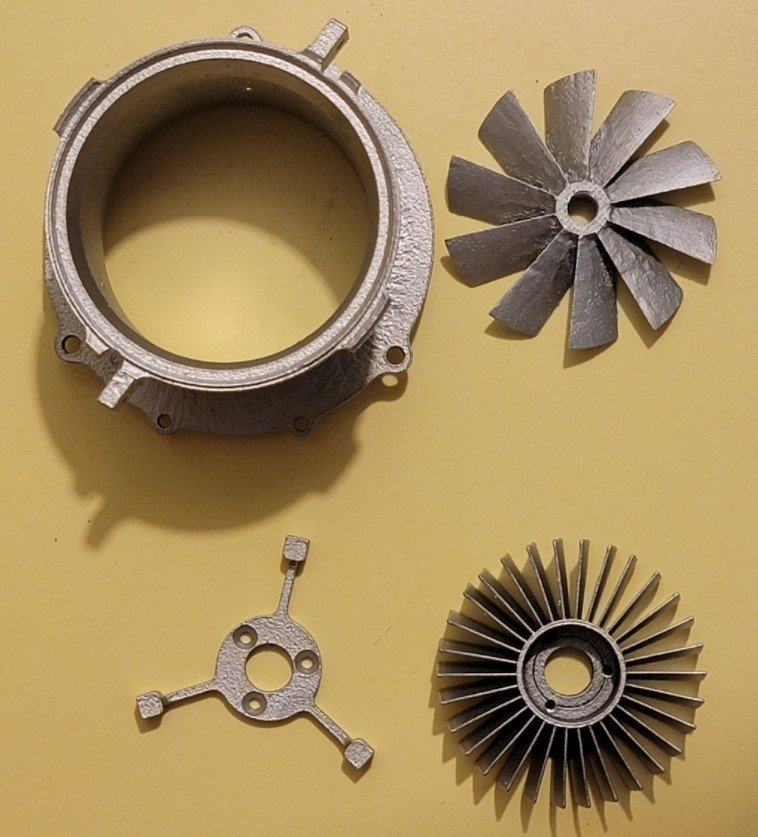

- Compressor

APOP designed a single-stage axial compressor to function in conjunction with the pre-existing single-stage radial compressor. The goal is to increase the compressor pressure ratio by 25%, which in turn will increase the thrust production and decrease the thrust specific fuel consumption of the JetCat. Both the rotor and stator are homogenous pieces of aluminum-silicon alloy manufactured via direct metal laser sintering (DMLS) - the first of their kind.

- Nozzle

The optimized nozzle has been designed and a prototype has been manufactured for testing. This new nozzle is projected to achieve an exit velocity of around 0.93 Mach, producing 35% more thrust than the stock engine. Following testing of the prototype, design modifications will be made and a final design will be manufactured.

- Heat Exchanger

The heat exchanger design has been completed and the team is working on manufacturing the heat exchanger for testing. With the addition of the heat exchanger, the team hopes to increase the atomization of the fuel to achieve a more complete combustion.

- Materials and Manufacturing

Material suitability to reduce weight while retaining performance was assessed. The subteam explored different manufacturing techniques and coordinated confirmation of CAD model accuracy.

More Than A "School Project"

APOP is led by a Senior Capstone Team, but welcomes and encourages students of all areas of study and abilities to join our team! APOP is a platform for personal and professional development outside of the traditional school project environment. We maintain a collaborative learning environment and pride ourselves on providing ways for all students to meaningfully contribute.

You are welcome to join us as a member of one of our following subteams:

- Compressor

- Fuel

- Materials/Manufacturing

- Nozzle

Volunteer Roles

Volunteers have extensively participated in manufacturing, testing, test stand and heat exchange design, overall CAD modeling, cost analysis, and research. There are many opportunities to be involved at different levels and the team works hard to find tasks that suit and help expand your skill set.

2014-2015

Afterburner Nozzle

2016-2017

Supersonic Nozzle

2018-2019

Increased Thrust/Weight Ratio

2020-2021

Compact & Low-Loss S-Duct Inlet.

2015-2016

Combuster Bypass/External Combuster

2017-2018

Cold Start

2019-2020

Anti-Windmilling & Thrust Vector Control.